Can product designers really change the world

Monday, July 22, 2013 at 05:24PM

Monday, July 22, 2013 at 05:24PM

idea,

idea,  materials app,

materials app,  process in

process in  concept,

concept,  ideas,

ideas,  the future

the future  Watch all my videos on Product Tank TV

Watch all my videos on Product Tank TV

A product design blog containing unique observations, advice and ideas to improve objects from the mind of Product Tank.

You can subscribe to receive my future blog posts by email, each time I publish new content - just click on the orange RSS symbol (on the right) and you will be taken to feedburner.

You can subscribe to receive my future blog posts by email, each time I publish new content - just click on the orange RSS symbol (on the right) and you will be taken to feedburner.

Monday, July 22, 2013 at 05:24PM

Monday, July 22, 2013 at 05:24PM

idea,

idea,  materials app,

materials app,  process in

process in  concept,

concept,  ideas,

ideas,  the future

the future  Sunday, June 23, 2013 at 03:18PM

Sunday, June 23, 2013 at 03:18PM  I was given the book 'Prototyping and Modelmaking for Product Design' for Christmas. Since then I've been referring to it. Many of the processes and techniques I already use on many of my projects, but it is a great resource especially for students or those new to making models for product design. It covers lots of processes many of which i didnt know much about. I suppose in some respects I wanted to check if the techniques that I've been using could be improved or were out of date as I am quite a traditional model maker, due to the availability of materials and resources, (we'd all like a rapid prototype machine, but one is currently out of my price range). I have developed lots of techniques to get around not having the right tools, or to do things more cheaply or reuse what I've got. But for the whole overview, from the professionals, this book is really good.

I was given the book 'Prototyping and Modelmaking for Product Design' for Christmas. Since then I've been referring to it. Many of the processes and techniques I already use on many of my projects, but it is a great resource especially for students or those new to making models for product design. It covers lots of processes many of which i didnt know much about. I suppose in some respects I wanted to check if the techniques that I've been using could be improved or were out of date as I am quite a traditional model maker, due to the availability of materials and resources, (we'd all like a rapid prototype machine, but one is currently out of my price range). I have developed lots of techniques to get around not having the right tools, or to do things more cheaply or reuse what I've got. But for the whole overview, from the professionals, this book is really good.

book review,

book review,  process,

process,  product design,

product design,  prototyping in

prototyping in  model making,

model making,  review

review  Wednesday, May 22, 2013 at 05:09PM

Wednesday, May 22, 2013 at 05:09PM

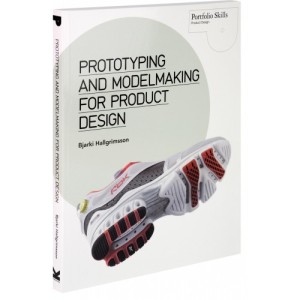

When I am designing a product I often only focus on the products relationship with the end user, without realising all the other areas where I can innovate. Products are manufactured, stored, delivered to warehouses, shipped in containers, displayed on shelves, taken home, used and kept in cupboards, cleaned etc. The life of a product does not begin when the customer opens the packaging. If I can save weight, materials, number of parts, size (flat pack), storage, ease of part replacement, ease of dis-assembly, then I am making huge cost savings and environmental savings, etc. There are loads of areas within product design where a designer can make a huge difference, a long time before it has reached the end user and a long time after and all too often I think this is overlooked.

Tuesday, May 14, 2013 at 03:23PM

Tuesday, May 14, 2013 at 03:23PM

The uncle of a friend of mine came up with an idea for a product; what the product was is not important, suffice to say, it was an idea so commercially bad, it was the chocolate tea pot of bad ideas. He wanted to take the design to market and with no product design experience, conducted a brief internet search and found an experienced Product Design company offering design evaluation services. From the website they had all the right bells and whistles and offered to evaluate the design free of charge. He went along to meet them and they reviewed his idea and surprisingly told him it had legs. The next step would be for their patent team of highly experienced patent experts to do a search to check if the idea had not already been patented. My friends uncle, parted with the cash (a princely sum) to allow the initial search to be conducted. The fee seemed steep, but they assured him that there would be a lot of hand holding along the way and their experts were, well… experts. Unsurprisingly, the initial search came back with articles of a similar nature, but nothing that was close to his idea (with good reason, his idea was a howler). For the next stage, the company would prepare various sketches to get rough tooling quotes and patent his idea. The fees were starting to increase, so my friend heard about his uncles’ folly and put him into contact with me. A few quick questions were enough. I felt like Simon Cowell on X-Factor. ‘Haven’t any of your friends or family told you, you can’t sing?’

‘No, they all say I have a beautiful voice’

It didn’t feel good.

'What do your friends and family think of your idea? Have you made a rough model to see if your idea will work?' I asked, he replied he hadn’t made a model, he had never done any of this before and didn’t really have any DIY skills. He also hadn’t told many people because he was worried about giving his idea away, but his wife thought he had a good idea, because she had experienced the problem. The idea was a classic combination of two products that worked spectacularly well at the jobs they were intended for separately and would work spectacularly badly when forced together to make a new multi-purpose object. ‘Go and buy these two items from a hardware store, cut a hole in one and stick the other through it, add a bit of gaffer tape and then go for a walk and try to use it,’ I advised – see what problems this creates and think around how to solve those problems. He did so and realised that he was potentially being taken for a ride.

Every design consultancy has mouths to feed and there are a lot of people out there with money who are having bad ideas, so sometimes paths may cross. I’m not condoning this, but there were faults on both sides. The consultancy should have told him that the idea needed radical development or scrapping and addressing the problem in another way, before taking a fee for a patent search. Also a few hours on the internet and in the shed would have solved many of his problems and highlighted many new ones. With a lot of work the design company may have been able to completely change the idea to create a half decent design, but would it ever be marketable and would my friends uncle have enough to invest to not only get it to market, but also market it so that people would invest or buy it, I don’t think so. With all my experience I could not see a way of making it work. My friends uncle had identified a problem, it was just the way he went about analyzing and solving it. You don’t have to be a designer or inventor to come up with good ideas, but there are a few things you have to do to test if they are any good.

Once you have identified the problem, you have to ask yourself does the problem really exist? Has it been solved in another way? In the space race, America spent 2 million dollars designing a ball point pen that would write in a zero gravity environment and the Russians just took a pencil (research suggest that this example maybe a myth but it does nicely illustrate a point). If indeed you have found a problem without a satisfactory solution, then you have to research to see if it hasn’t already been done and you are just not aware of it (the internet is great for this). Then, you don’t need to be good at sketching or making models, but I cannot stress enough, you do need to make rough, quick models to find the faults with your idea. Use card board, plasticine, even salt dough – anything you can get your hands on and test your ideas on family and friends before approaching a designer – whatever it takes to avoid that chocolate tea pot. I'm going to blog around this a lot more in the future.

advice,

advice,  process,

process,  product design in

product design in  process,

process,  product design advice

product design advice  Saturday, January 10, 2009 at 01:32PM

Saturday, January 10, 2009 at 01:32PM  Much of our computer waste is recycled in India by children sat over gas burners, melting circuit boards to try and extract the metals (picture courtesy of Greenpeace India), many get lead poisoning from the fumes. I was trying to think of a solution, improving the salvaging conditions with extractor fans and better equipment is one approach, but I focused on the PCB. I started wondering if you could print a PCB, I’ve seen paint that has enough of a metal base to conduct electricity. I then saw the work of Sam Buxton, a designer who acid etches sheet metal. If the problem of extraction is based on the current method of board manufacture, my though was to acid etch (or laser cut) the metal before bonding, then adhere it to the board using a water-soluble solution. This would allow much easier recycling, because the board wouldn’t need to be robust enough to survive an acid bath. Dipping the board in a tank of water would allow the etched metal to come away. The board could then become more easily recyclable.

Much of our computer waste is recycled in India by children sat over gas burners, melting circuit boards to try and extract the metals (picture courtesy of Greenpeace India), many get lead poisoning from the fumes. I was trying to think of a solution, improving the salvaging conditions with extractor fans and better equipment is one approach, but I focused on the PCB. I started wondering if you could print a PCB, I’ve seen paint that has enough of a metal base to conduct electricity. I then saw the work of Sam Buxton, a designer who acid etches sheet metal. If the problem of extraction is based on the current method of board manufacture, my though was to acid etch (or laser cut) the metal before bonding, then adhere it to the board using a water-soluble solution. This would allow much easier recycling, because the board wouldn’t need to be robust enough to survive an acid bath. Dipping the board in a tank of water would allow the etched metal to come away. The board could then become more easily recyclable. A board would be layered with adhesive (1), the etched metal sheet laid on top (2) holes would be drilled (3) and the individual boards cut out (4).

pcb,

pcb,  process,

process,  product design in

product design in  ideas

ideas