How to prototype live hinges

Thursday, October 3, 2013 at 04:19PM

Thursday, October 3, 2013 at 04:19PM

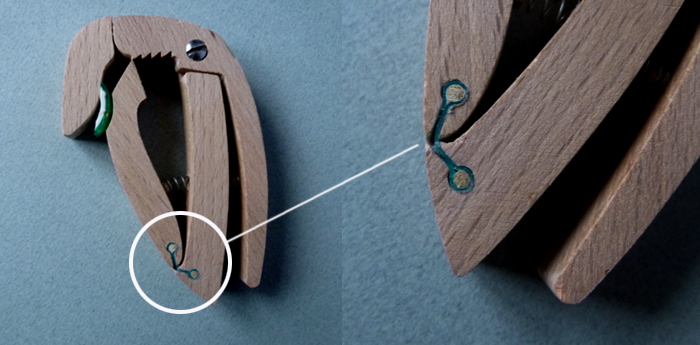

Many times I have a design that I want to have a live hinge. The easiest way I have found to prototype live hinges when making working models is to slot thin strips of polypropylene into slots cut into my model. By drilling holes first, then cutting a slot leading into the hole, I can easily control the depth of the slot and also have a means of pushing the polyprop hinge out if you want to make adjustments. Its important to select the right saw blade thickness to polyprop thickness (I find a junior hacksaw blade works best) and then double the polyprop up. For added security you can also push pegs into the holes. In the images of a pan lid locking handle (above) and clothes peg (below) the main material used is beech wood, with pieces of bamboo skewers used to lock the polyprop in place and pull the hinge taught on the clothes peg.

live hinges,

live hinges,  model making in

model making in  model making,

model making,  process

process