This weekend I finally completed the car project I have been working on for... too long. Its been a difficult project (every thing that could have gone wrong did), so I'm not sure how I feel about the end result - if I had to do it all over again... I'd probably walk away. Of course there are loads of things I'd like to have done a lot better and things I'd completely change. As usually happens half way through this project, I came up with a much better idea for another car, its a real humdinger in the sketch pad. Unfortunately it was such a radical change that I couldn't incorporate it into this design. So I was faced with the tricky descision of scrapping several months work or pushing on. Much squinting and tongue chewing later, I decided to push on and so now, at the end, I'm glad I did - although this could be the wine talking!

All I have to do is polish a few images, edit a video and release it on the web to begin its new life on its own (fly my pretty). I have learnt a lot whilst doing this project that I am sure will benefit me in the future, especially techniques for covering things in paper, which is a great for quickly covering over unsightly mistakes - it feels like the motto of this project should be, if it's unfinished, glue some paper over it and it will (hopefully) be ok. Other mottos would also include, don't try and make round things without a lathe, dont decide it would be fun to make the interior as well as the exterior and do decide how the doors are going to open at the start, rather than thinking 'Oh I'll resolve that minor detail later on'. Yee Haa

Tuesday, January 27, 2015 at 03:50PM

Tuesday, January 27, 2015 at 03:50PM

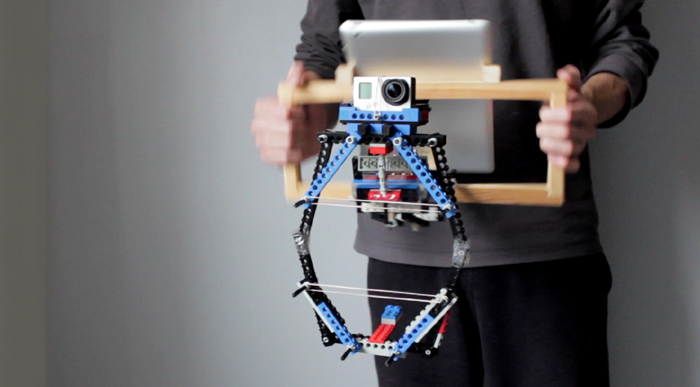

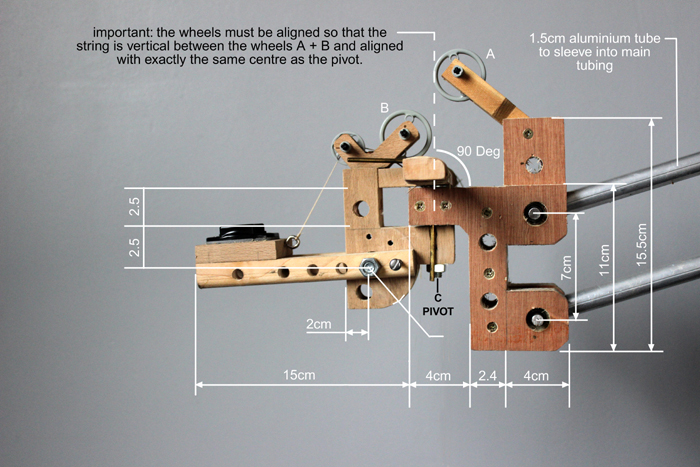

camera crane,

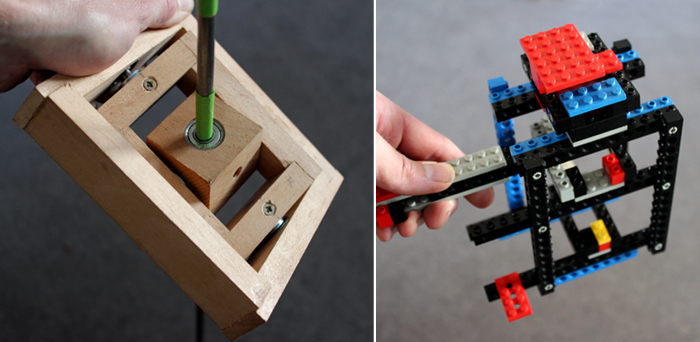

camera crane,  plans in

plans in  model making,

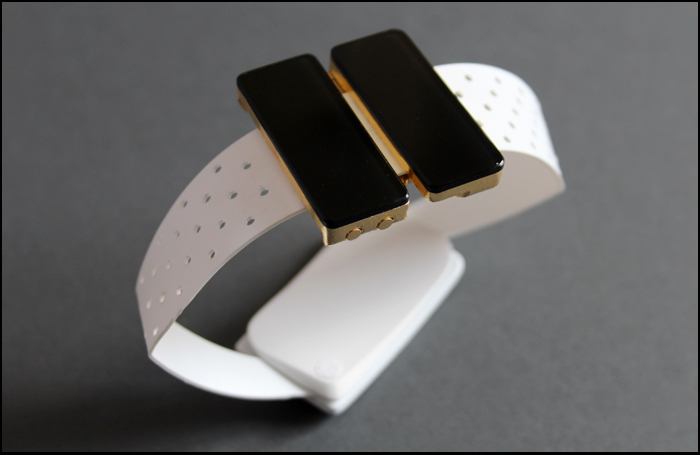

model making,  prototype

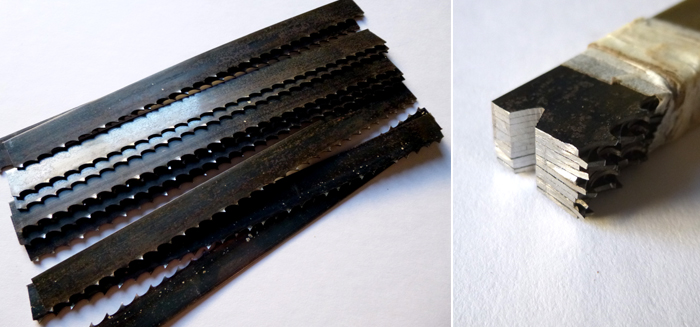

prototype